A 10‑megawatt green hydrogen facility that will power the Kruger pulp mill in Kamloops, B.C. with clean energy is an example of Indigenous Canadian leadership in the sector, a project partner said, making it a first-of-its-kind project.

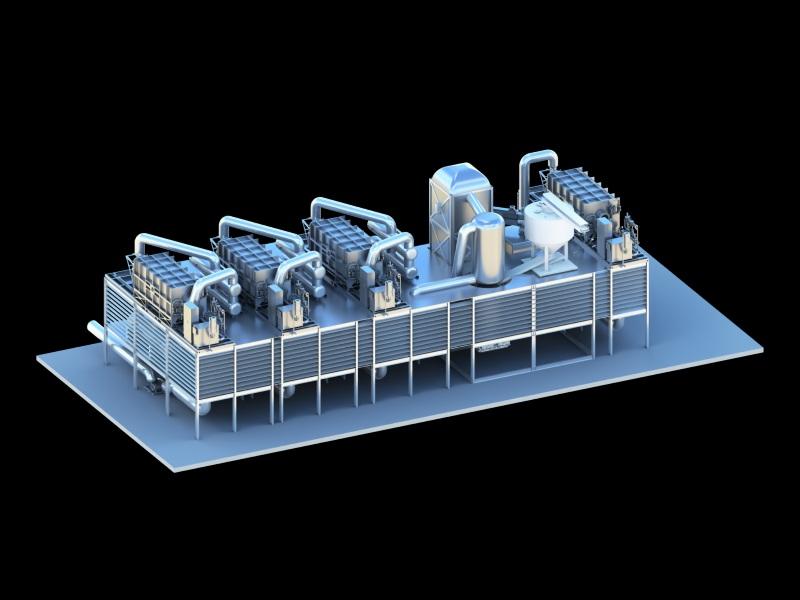

Sc.wén̓wen Economic Development, Kruger Kamloops Pulp L.P. and Elemental Clean Fuels announced a partnership earlier this month to develop the Kamloops Clean Energy Centre (KCEC). The facility is designed to partially decarbonize the mill's operations with hydrogen made on site.

A $21.7-million effort, it is designed to produce up to four tonnes of hydrogen and 32 tonnes of oxygen per day. The hydrogen will partially power the facility and a portion of the oxygen will be reused in the mill’s operation, Zachary Steele, CEO of Elemental, said in an email exchange with Sustainable Biz Canada.

Sc.wén̓wen Economic Development is the business arm of the Tk̓emlúps te Secwépemc, a local Indigenous community. Kruger Inc., a Montreal-based pulp and paper, lumber and energy company acquired the mill from Domtar in 2022. Elemental is an Oyster Bay, N.Y.-headquartered low-carbon fuel project developer with an office in Kamloops.

“By integrating green hydrogen into our operations, we will be reducing emissions, supporting a circular economy, and contributing to British Columbia’s clean energy targets,” Irene Preto, general manager of the Kruger Kamloops Pulp Mill, said in the announcement.

About the KCEC

The KCEC will produce hydrogen fuel and oxygen by splitting water with electricity in an electrolyzer. The machine will be powered by the province’s low-carbon grid, making it green hydrogen.

Hydrogen will be used to offset 16 per cent of the natural gas that powers the mill’s kiln burner, reducing approximately 7,000 tonnes of carbon dioxide emissions per year, Steele said.

The oxygen can be used in the mill’s wastewater treatment and pulp bleaching processes, he added, “further improving operating efficiencies onsite.”

Elemental began working with Kruger and Tk̓emlúps te Secwépemc in early 2024 after it acquired a stake in Kamloops-based company Cariboo Clean Fuels, Steele said. The Cariboo team was developing the project with Tk̓emlúps te Secwépemc and the mill’s management for months, “leveraging Cariboo’s experience, relationships, and presence in the region,” he continued.

“Hydrogen production is not first-of-a-kind by itself, but the elements making up our project are,” Steele said, highlighting how the KCEC is a First Nation-led hydrogen production project.

The Canadian paper and pulp industry is not a large source of carbon emissions, the Canadian Climate Institute says. But the industry’s energy intensity and emissions intensity have trended upward over time.

To tackle the carbon emissions of the paper and pulp industry, companies such as Vancouver-based CO280 are developing carbon capture projects in mills. U.S. company Mantel is partnering with Kruger on development of a carbon capture project at Kruger’s Wayagamack Mill in Quebec.

The Canadian Climate Institute says companies in the sector can reduce carbon emissions with electrification (heat pumps, electrified dryers), fuel switching (biomass, renewable natural gas) and energy efficiency (waste heat recovery).

Project partner hopes KCEC will boost hydrogen industry

Cleantech news site CleanTechnica published an article critical of the project, arguing the mill's natural gas consumption could be reduced by “avoiding hydrogen entirely, using bog standard oxygen manufacturing equipment and an electric kiln or two, with more reliable technologies that are more easily serviced.”

In response, Steele said, “we believe hydrogen has more uses then electricity. In addition to carbonation via offsetting natural gas consumption, hydrogen has uses in the mobility sector, with advantages over electric-driven engines.”

He also noted hydrogen can be used as a feedstock to create clean-burning fuels such as methanol.

“We believe a diverse energy mix creates a more resilient sustainable energy,” Steele said. Developing hydrogen projects such as KCEC “will lead to greater adoption, more projects, wider application, and cheaper, more efficient energy solutions for Canada as technologies scale up,” he continued.

The KCEC project is in the front-end engineering and design phase. A schedule for the project was not disclosed in the announcement.

“Our goal is to replicate these projects throughout Canada,” Steele said.